Preface:

Welcome to use our products. In order to make you better use this machine, we hereby propose the following suggestions to you:

1.The operator must be fully familiar with and master the performance and working principle of the machine before operating the machine.

2.The machine shall be installed on a flat site with flatness error no more than 5mm/㎡.

3.After the machine is installed, there should be a reliable grounding wire to prevent damage caused by electric leakage.

4.The "prompt" in the manual is to remind that the wrong operation may cause harm to human body or damage the machine, and attention must be paid during operation.

The product shall be subject to the real object, and the manual is for reference only. Any minor change is subject to no further notice. If there is any problem when using the product, please contact the supplier in time.

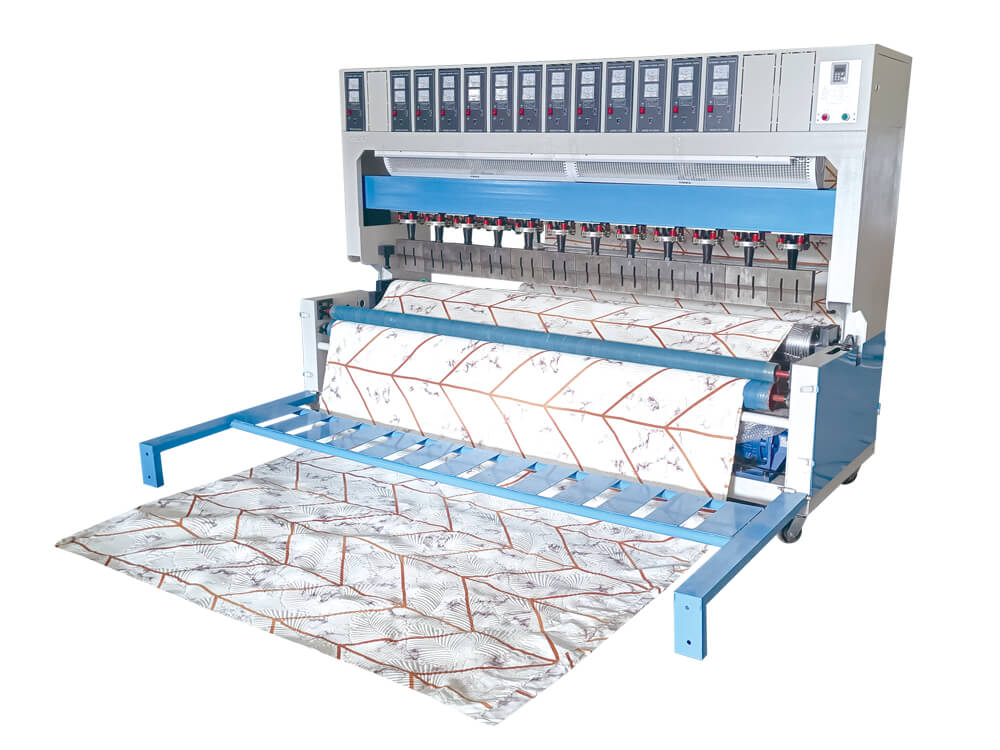

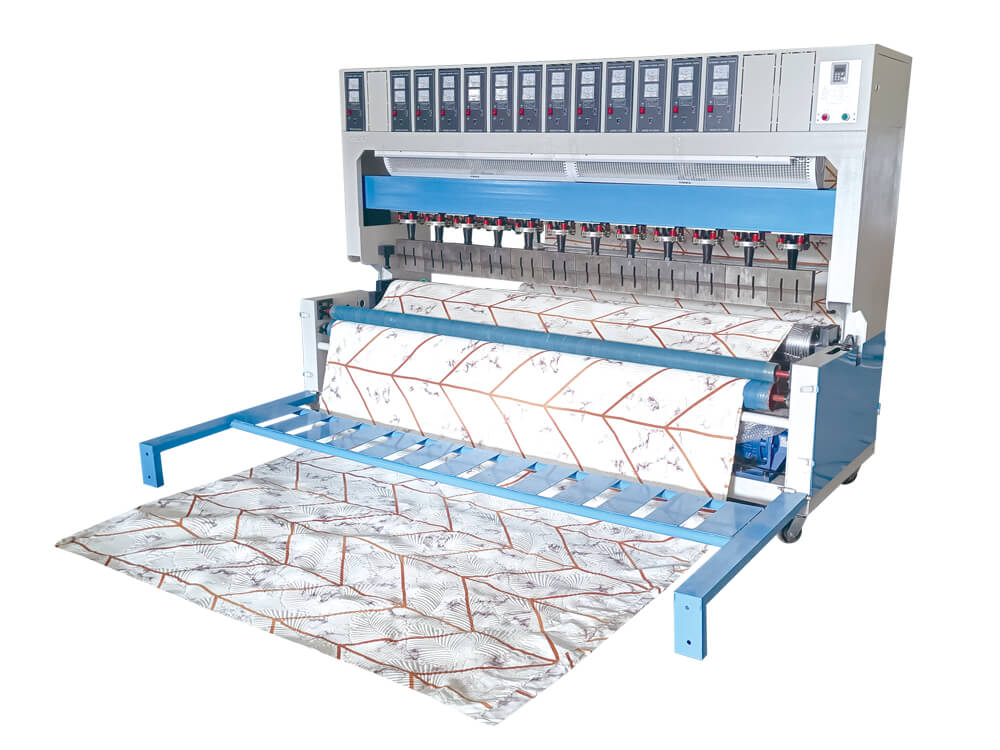

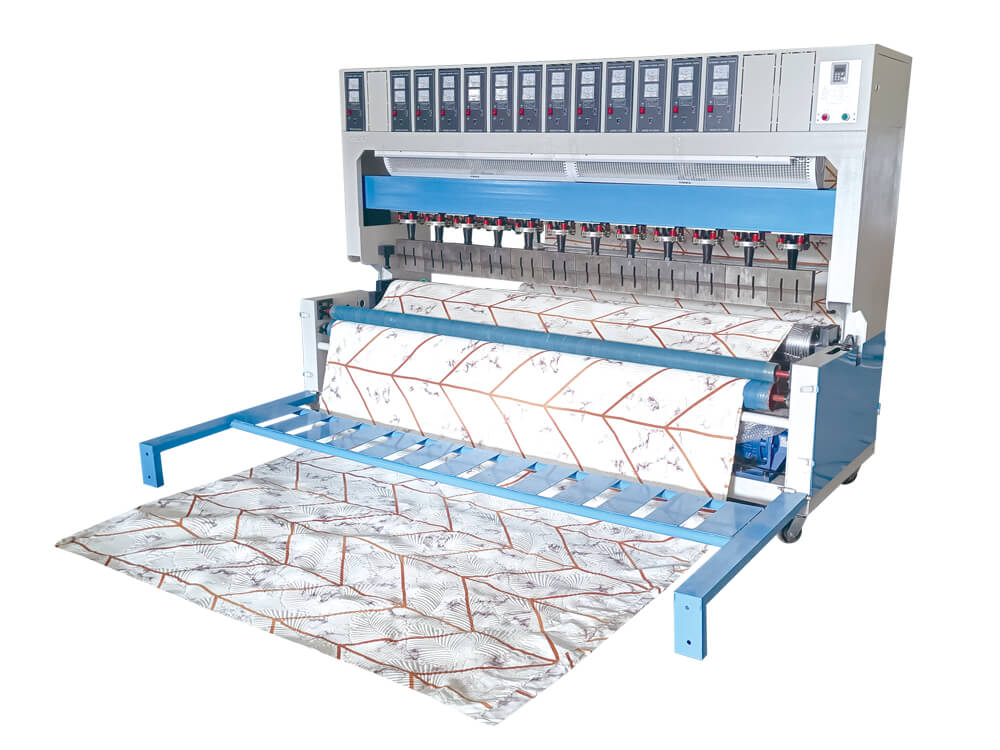

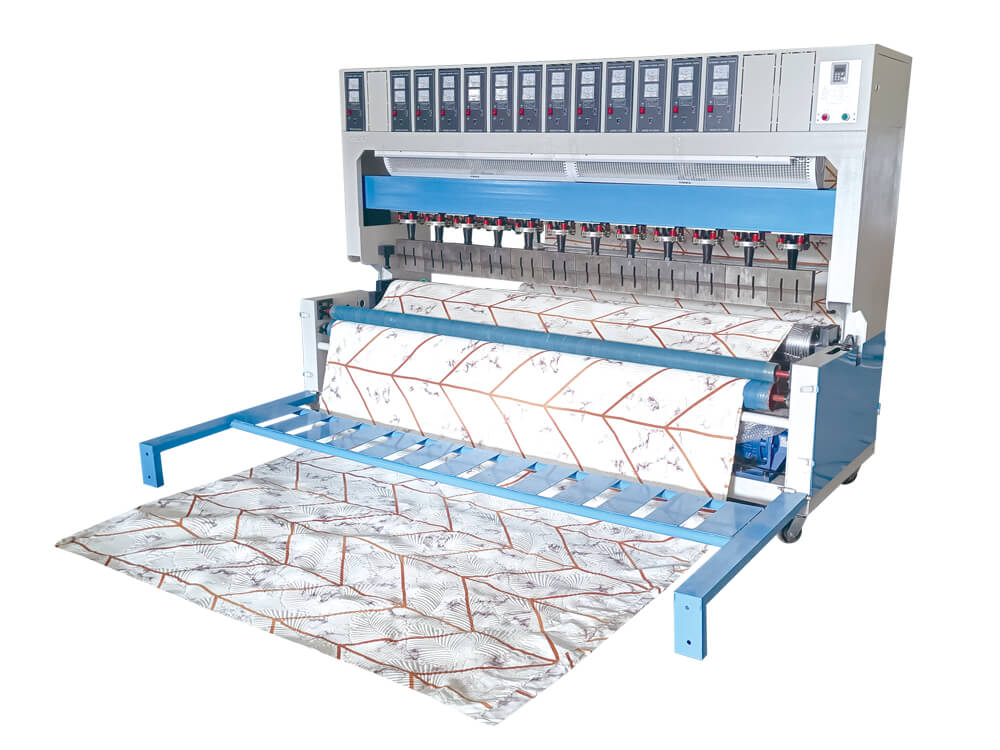

Model | QZ3000 | QZ2800 | QZ2600 | QZ2300 | QZ1850 |

horn | 20 | 18 | 17 | 15 | 12 |

breadth (mm) | 3079 | 2800 | 2617 | 2309 | 1847 |

speed (m/h) | 300-1000 | 300-1000 | 300-1100 | 300-1500 | 300-1800 |

power | AC380/11.5kw | AC380/11.5kw | AC380/10.3kw | AC380/7.8kw | AC380/6.3kw |

Machine size (mm) | 3465×1800×1070 | 3290×1800×1070 | 3006×1800×1070 | 2700×1800×1070 | 2241×1800×1070 |

Packing size (mm) | 3665×1140×890 | 3490×1140×890 | 3206×1140×890 | 2900×1140×890 | 2441×1140×890 |

Operation:

1. The ultrasonic welding time is short, and automatic sewing is needle-free, which saves the trouble of changing stitches frequently. The sewing speed is 5 to 10 times that of needle sewing.

2. Because the needle is not used, the situation of broken needle remaining in the material during the sewing process is avoided, and the potential safety hazard is eliminated. It is a new generation of safety and environmental protection product.

3. There is no broken joint of traditional suture, with strong adhesion, clear embossing, more three-dimensional relief effect on the surface, and more high-grade and beautiful products.

4. After processing, the finished product has no pinhole and no water seepage, and has more waterproof and warm effect.

5. By using the roller mold, it is easy to change the mold, and can sew out the ever-changing and complex discontinuous and symmetrical patterns. It can also develop various flower patterns according to customer needs.

6. This machine has a high degree of automation and intelligence. The computer touch screen operation ensures that the upper and lower materials are always aligned when sewing the table. The processing loss is low, and the product is more flat and stable.

Explain:

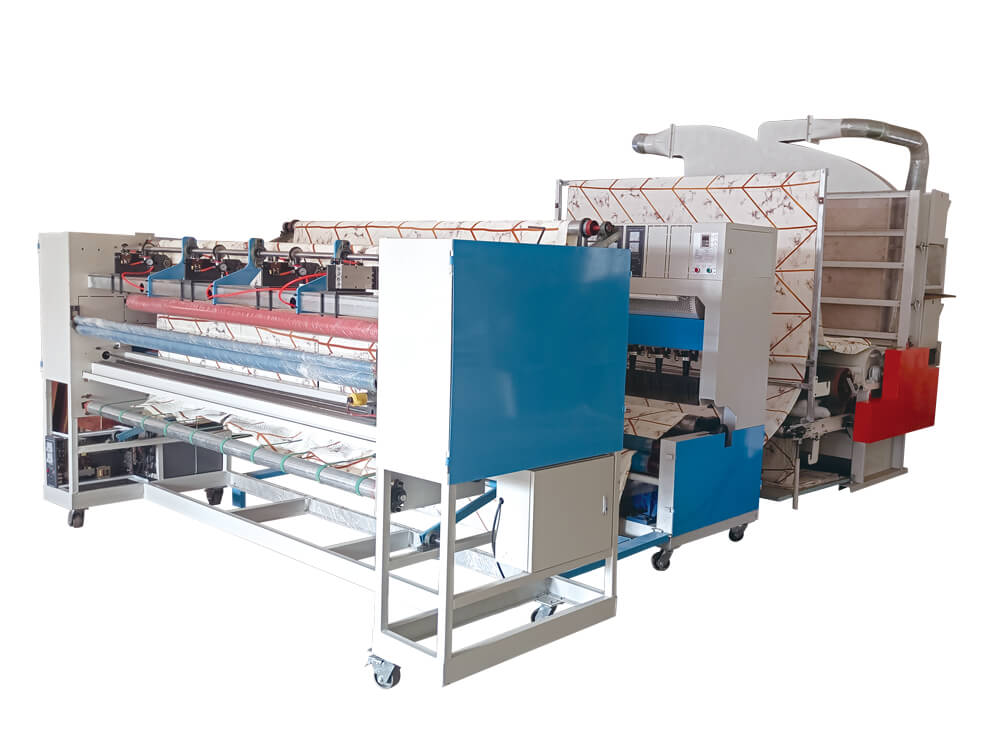

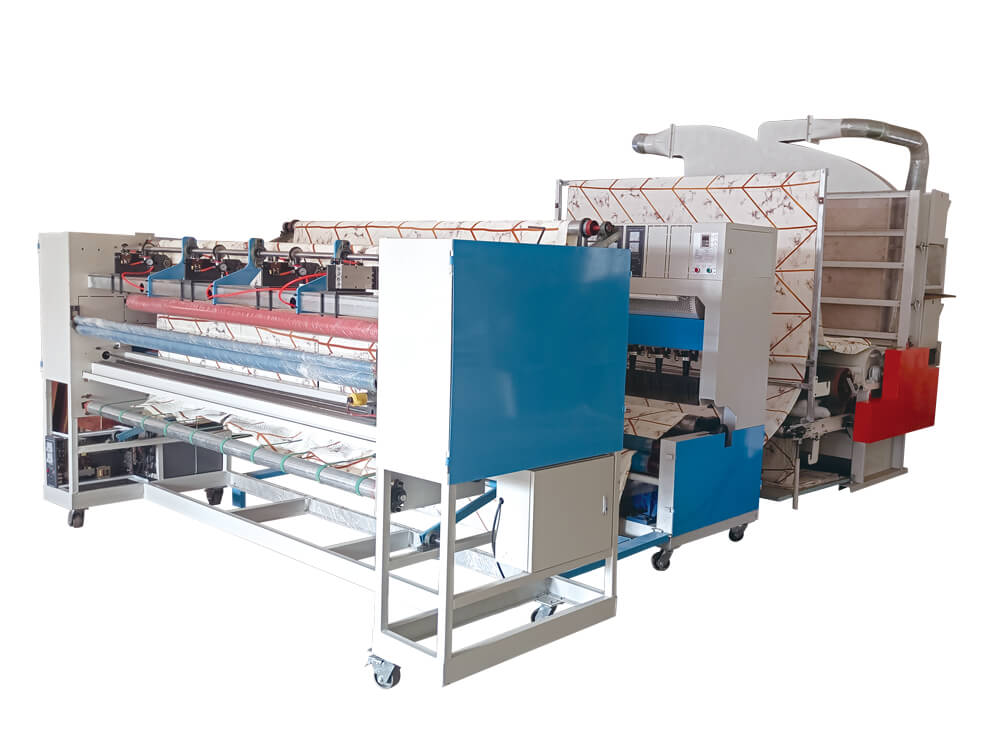

1. Material rack: put the fabric and lining in order, and adjust the deflection angle of the tensioner according to different lining to obtain the desired tension.

2. Electrical control: the system adopts three-phase four-wire power supply with voltage of 380V. When operating the equipment, check whether the power supply is turned on, whether the air source has gas, whether the transmission mechanism of the equipment is normal and whether the personnel are safe.

3. Startup steps:

(1) Turn on the power switch

(2) Start cooling fan

(3) Start the ultrasonic switch, and check whether the case and the vibrating head are normal and wavy (feel it with your hands)

(4) The embossing speed is adjusted to about 0.8, and the air valve and embossing roller are pulled

(5) Check whether the pattern is clear and obvious

Fine adjust both sides of the roller during adjustment Φ 36 large screws and vibrating head screws, adjust to clear pattern, a. first adjust the four screws on the amplitude rod( Φ 17) Leveling, to ensure that there is a gap between each vibrating head, first adjust from the middle No. 5 vibrating head to the left and right sides in order to ensure that the gap between each vibrating head and the flower roller is kept at a level. B. After the vibration head is leveled, tighten the large screws (outer hexagon nuts) on both sides of the roller Φ 36) Lower it a little, then lift it up, and slowly tighten the nut with a large wrench (left rotation means lowering, right rotation means raising) until the gap between the flower roller and all vibration heads is between 0.5 (depending on the material).

(6) If both sides of the flower roller are pressed with patterns and there is no pattern in the middle, it means that the height of the flower roller is enough, and the vibration head in the middle is not lowered enough. At this time, there are two adjustment methods: (1) if the number of vibration heads that are not pressed is large, raise the vibration head that can be pressed on both sides, and then adjust the height of the flower roller, so as to ensure that the gap between the flower roller and the vibration head is consistent, and all corresponding patterns can be pressed. (2) The vibrators on both sides do not move, and the height of the flower roller does not move. Adjust the vibrators in the middle, and adjust 4 Φ The screw of 17 falls down as a whole until it can hold the flower shape.

(7) If one side of the flower roller is pressed, and the other side is not pressed, turn the big screw on the side that is not pressed Φ 36 Turn it to the right until it can be pressed. At the same time, the side that can be pressed at the beginning is slightly lower to prevent it from touching the flower roll and scratching the flower roll.

(8) Turn on the rewind to run normally, and press the emergency stop button in case of an emergency.

(9) Traction device: in order to make the composite materials enter the coiling smoothly, the mechanism can transfer the finished composite products with flush edges to the coiling mechanism for coiling, and adjust the gap of the pressure roller to change its traction force.

Winding device:

The composite material needs to be rolled for transportation and storage. The linear speed of the device is adjustable.

Installation and adjustment:

1. All parts of the machine shall be aligned before and after installation.

2. Check the connection of water pipe and other pipe joints to ensure there is no leakage or looseness.

3. The transmission chain shall operate normally without jamming, and the protective cover shall be installed.

4. Check the fastening of each connection, add proper amount of heavy lubricating oil to the sprocket and chain, and check whether the electrical wiring is correct and the rotation direction of the motor.

The test run can be carried out after the above items are normal. The test run time shall not be less than 2 hours. If any abnormality is found, it shall be eliminated in time.

Maintenance:

1. The lubricating oil of the reducer should be changed every six months.

2. The lubricating oil shall be replaced after the motor is used for one year.

3. After use, it must be cleaned in time to clear the residual glue and dirt in all parts of the machine.

4. The chain shall be lubricated normally and tensioned in time.

5. The electrical circuit shall be well insulated

微信扫码 关注我们

微信扫码 关注我们

24小时咨询热线15962903769

移动电话13814728896

Copyright © 2023 All Rights Reserved. 苏ICP备2023015758号-1 XML地图 地址:Xitong Industrial Zone, Nantong City, Jiangsu Province 南通网站建设